Model number:SBS-SR-HST

Temperature: -50ºC - +200ºC

Shrink temperature: 90ºC - 170ºC

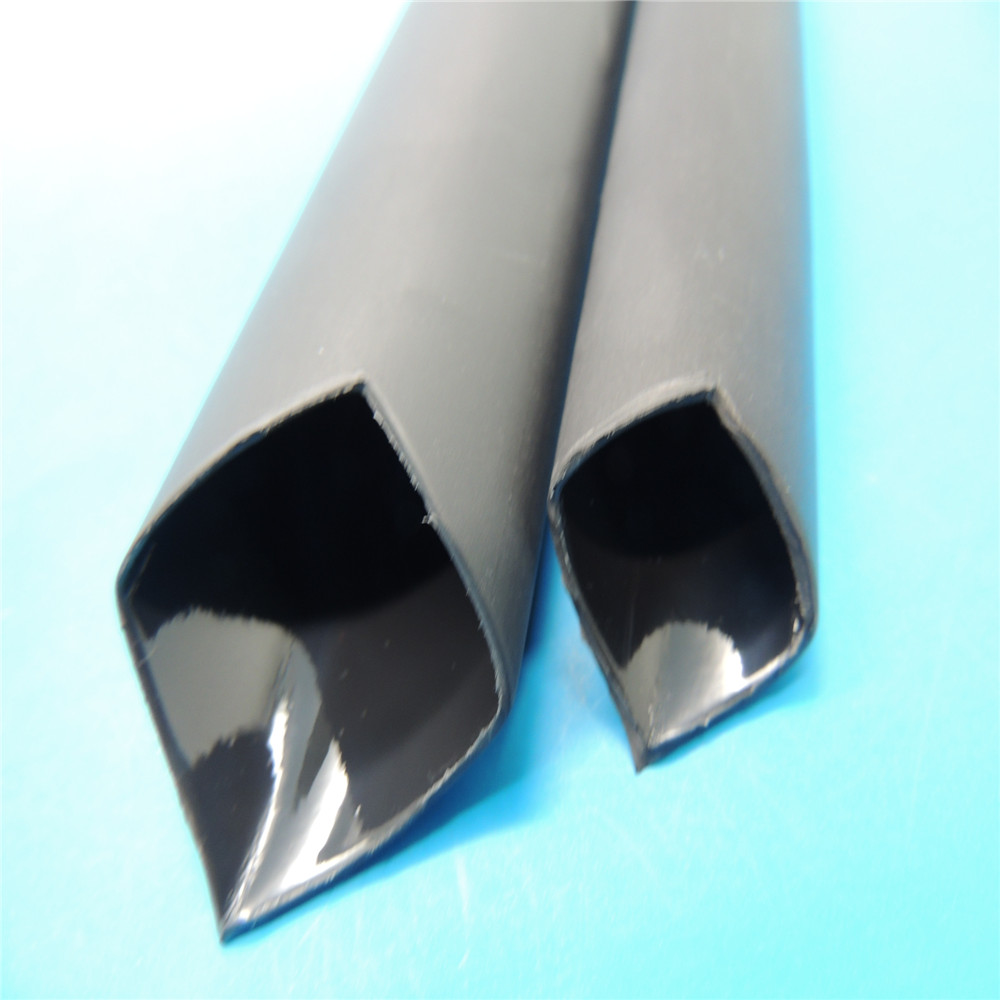

Shrink ratio: 1.7:1 ( 2:1 shrink ratio can be customized)

Structure

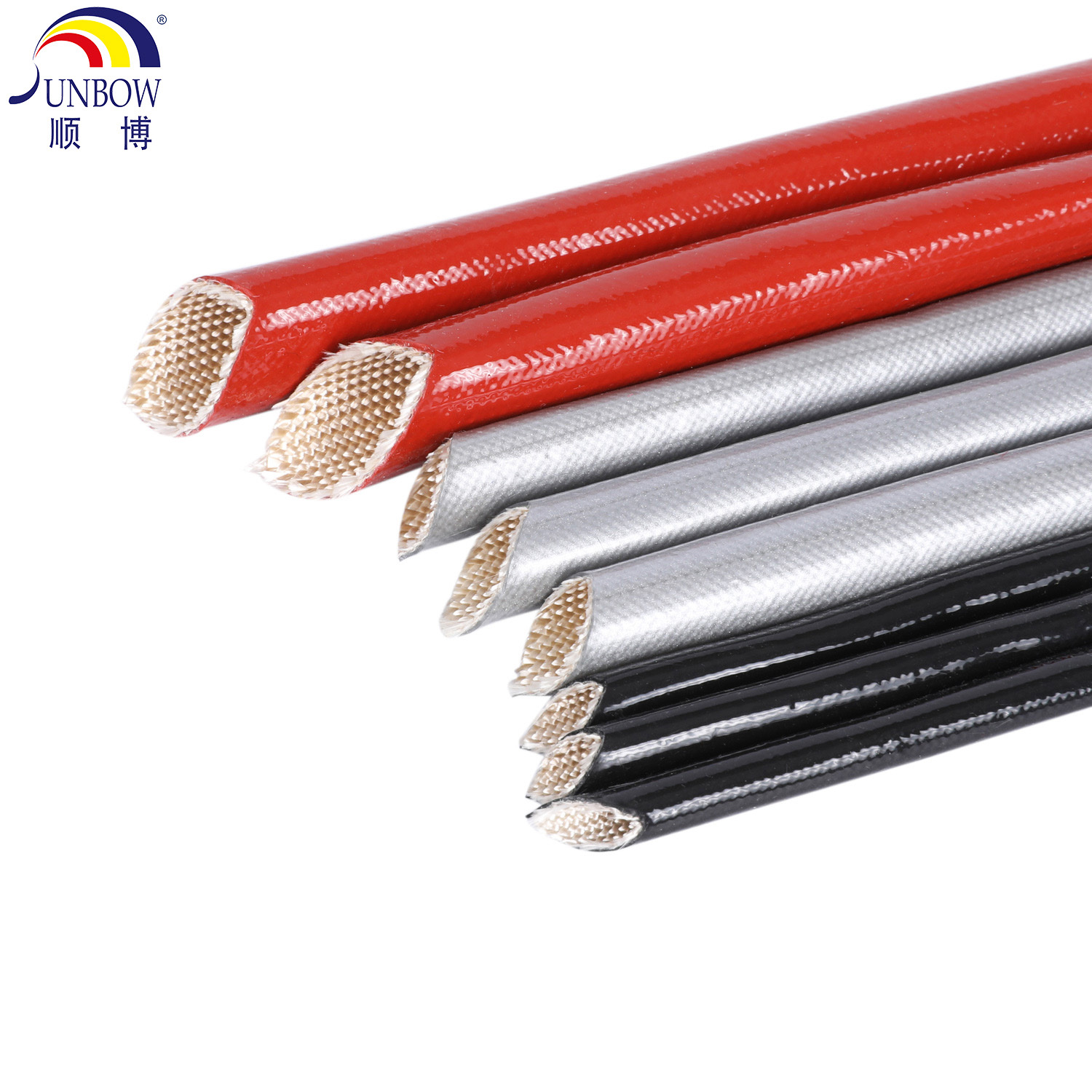

Silicone rubber heat shrinkable tube is made of silicone rubber modified with heat shrinkable silicone tube, not only has the general silicone tube itself excellent performance, high temperature, high pressure, flame retardant, soft and flexible, But also has a thermal shrinkage performance, good resistance to thorn damage mechanical properties.

Usage

It is widely use in electrical protection, resistor, capacitor, aerospace, medical instrument etc.

Specification

Performance | Flame retardant | Normal type |

Tensile strength MPa(Kg/cm2) | 4.2 | 4.5 |

Elongation at break % | 300 | 300 |

Volume resistivity Ω·m(Ω·cm) | 2×1012(2×1014) | 2×1012(2×1014) |

Dielectric strength KV/mm | 18 | 18 |

Use temperature rangeºC | -50~+200 | -50~+200 |

Axial shrinkage% | 40% | 40% |

Shrink temperature ºC | > 120 | > 120 |

Concentricity % | ≥65 | ≥65 |

Flammability (Oxygen Index) | ≥28 | ≥28 |

Dimension

Size | Shrink size Before shrink | Wall thickness | After recovery | Thickness after shrink | Packing | |

I.D. | mm | I.D. | mm | m/roll | m/pcs | |

Φ1.0 | 1.0 | 0.5±0.05 | 0.6 | 0.8±0.05 | 200 | |

Φ1.5 | 1.5 | 0.5±0.05 | 0.8 | 0.8±0.05 | 200 | |

Φ2.0 | 2.0 | 0.5±0.05 | 1.2 | 0.8±0.05 | 200 | |

Φ2.5 | 2.5 | 0.5±0.05 | 1.5 | 0.8±0.05 | 200 | |

Φ3.0 | 3.0 | 0.5±0.05 | 1.8 | 0.8±0.05 | 200 | |

Φ3.5 | 3.5 | 0.5±0.05 | 2.0 | 0.8±0.05 | 200 | |

Φ4.0 | 4.0 | 0.5±0.05 | 2.5 | 0.8±0.05 | 200 | |

Φ4.5 | 4.5 | 0.5±0.07 | 2.8 | 0.8±0.05 | 200 | |

Φ5.0 | 5.0 | 0.5±0.07 | 3.0 | 0.8±0.05 | 200 | |

Φ6.0 | 6.0 | 0.5±0.07 | 3.8 | 0.85±0.05 | 100 | |

Φ7.0 | 7.0 | 0.5±0.07 | 4.0 | 0.85±0.05 | 100 | |

Size | Shrink size Before shrink | Wall thickness | After recovery | Thickness after shrink | Packing | |

I.D. | mm | I.D. | mm | m/roll | m/pcs | |

Φ8.0 | 8.0 | 0.5±0.07 | 4.8 | 0.85±0.05 | 100 | |

Φ9.0 | 9.0 | 0.5±0.07 | 5.0 | 0.85±0.05 | 100 | |

Φ10.0 | 10.0 | 1.0±0.1 | 6.5 | 1.7±0.1 | 100 | |

Φ12 | 12.0 | 1.0±0.1 | 7.0 | 1.7±0.1 | 50 | |

Φ15 | 15.0 | 1.0±0.15 | 9.0 | 1.7±0.1 | 50 | |

Φ20 | 20.0 | 1.0±0.2 | 13.0 | 1.7±0.1 | 50 | |

Φ25 | 25.0 | 1.0±0.2 | 15.0 | 1.7±0.1 | 50 | |

Φ30 | 30.0 | 1.0±0.2 | 18.0 | 1.7±0.1 | 50 | |

Φ35 | 35.0 | 1.3±0.3 | 20.0 | 2.5±0.3 | 1 | |

Φ40 | 38.0 | 1.3±0.3 | 25.0 | 2.5±0.3 | 1 | |

Φ50 | 50.0 | 1.3±0.3 | 30.0 | 2.5±0.3 | 1 | |

Φ60 | 60.0 | 1.5±0.3 | 38.0 | 2.5±0.1 | 1 | |

Φ70 | 70.0 | 1.5±0.3 | 45.0 | 3.0±0.4 | 1 | |

Φ80 | 80.0 | 1.5±0.3 | 48.0 | 3.0±0.4 | 1 | |

Φ90 | 90.0 | 1.5±0.3 | 52.0 | 3.0±0.4 | 1 | |

Φ100 | 100 | 1.5±0.3 | 58.0 | 3.0±0.4 | 1 | |

Φ110 | 110.0 | 2.0±0.5 | 63.0 | 4.0±0.0.5 | 1 | |

Φ120 | 120.0 | 2.0±0.5 | 70.5 | 4.0±0.0.5 | 1 | |

Φ130 | 130.0 | 2.5±0.5 | 76.0 | 5.0±0.0.6 | 1 | |

Φ140 | 140.0 | 2.5±0.5 | 82.0 | 5.0±0.0.6 | 1 | |

Φ150 | 150.0 | 2.5±0.5 | 88.0 | 5.0±0.0.6 | 1 | |

*Other packing could be customized upon request.

*The thickness could be customized for 0.5mm~5mm thicker upon request.

![]()

![]()

.